Bag Dump Stations

An Innovative Debagging Station to Save Time and Money for Users of Powder and Bulk Solids

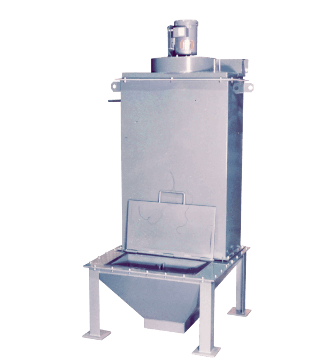

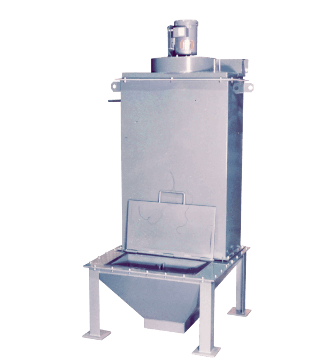

If you use powders or bulk solids in your operation, Griffin Filters' Dustless Debagger can save you time and money while keeping your air clean. This self-contained unit is both a fast, efficient debagging station plus a complete dust control system.

Designed by our experienced engineers and backed by over 40 years of know-how in the air pollution field, it is ruggedly built for years of service. The Dustless Debagger is made of heavy duty welded construction. Small and compact in size, it is 99% plus efficient. There is a choice of three bag cleaning methods: manual shake, motorized shake, and pulse jet.The filter bags and cleaning mechanism are accessible from grade level. Filter bag replacement is fast and easy through a rear door opening. Blower fan is top mounted or, as an option, side-mounted.Because of its small size and relatively lightweight, the debagger can be easily transported. It is shipped as two components, with bags installed, for convenient field assembly.

Blower fan is top mounted or, as an option, side-mounted.Because of its small size and relatively lightweight, the debagger can be easily transported. It is shipped as two components, with bags installed, for convenient field assembly.

When dropped on the recessed grating, the bag is split in half by the knives. There is no strain or reaching by the operator and, as there are no overhead obstructions, a hard hat need not be worn. The material falls into the hopper and the lighter, airborne particles are drawn upward and collected on the bags.

Your Choice of Three Bag Cleaning Methods

1. Manual Shake - 18 BDM

A manual shaker bag dump station is used primarily for intermittent duty where only periodic bag dumping is required. A hand crank is provided for manual bag cleaning once fan is shut off. A limit switch is provided for automatic activation of fan motor. User provides 115V/1ph/60hz electrical power for all electrical components.

2. Motorized Shake - 18 BDA

The motorized shaker bag dump station is used for continual bag dumping, where only momentary shut down for bag cleaning is allowed. A limit switch is provided for automatic activation of fan motor.Option - Control panel for automatic activation of shaker motor is available. Activation is accomplished when bag dump door opens and starts the fan. Closing the bag dump door stops the fan and energizes the bag cleaning cycle which operates for one minute.User provides 115V/1/60 electrical power for all electrical components.

3. Pulse Jet - 18 BDP

The pulse jet bag dump station is designed for continuous bag dumping where shut down is impractical.A limit switch is provided for automatic activation of fan motor and pulse controls.The control panel is supplied and includes two variable timers. One controls the duration of pulse and the other controls the interval between pulses.The user provides compressed air for operation of the cleaning cycle, 115V/1ph/60hz electrical power for electrical controls, 230-460V/3ph/60hz for fan motor.

| Customization |

- The Griffin Dustless Debagger is available in stainless steel or other special alloys.

- Sanitary smooth finishes are available for food grade applications.

- HEPA filters and silencers can be provided on the outlet of the fan. As an additional option, the blower can be side-mounted

- For use as a baghouse pre-coat system, larger storage hoppers and rotary airlocks can be supplied.

- Special coatings are available.

- Special motors are also available.

- Optional motor starters and wiring.

|

Blower fan is top mounted or, as an option, side-mounted.Because of its small size and relatively lightweight, the debagger can be easily transported. It is shipped as two components, with bags installed, for convenient field assembly.

Blower fan is top mounted or, as an option, side-mounted.Because of its small size and relatively lightweight, the debagger can be easily transported. It is shipped as two components, with bags installed, for convenient field assembly.